Maybe the four-legged hybrid robot shown walking, running and rolling in Pixar’s “The Incredibles” isn’t too far off.

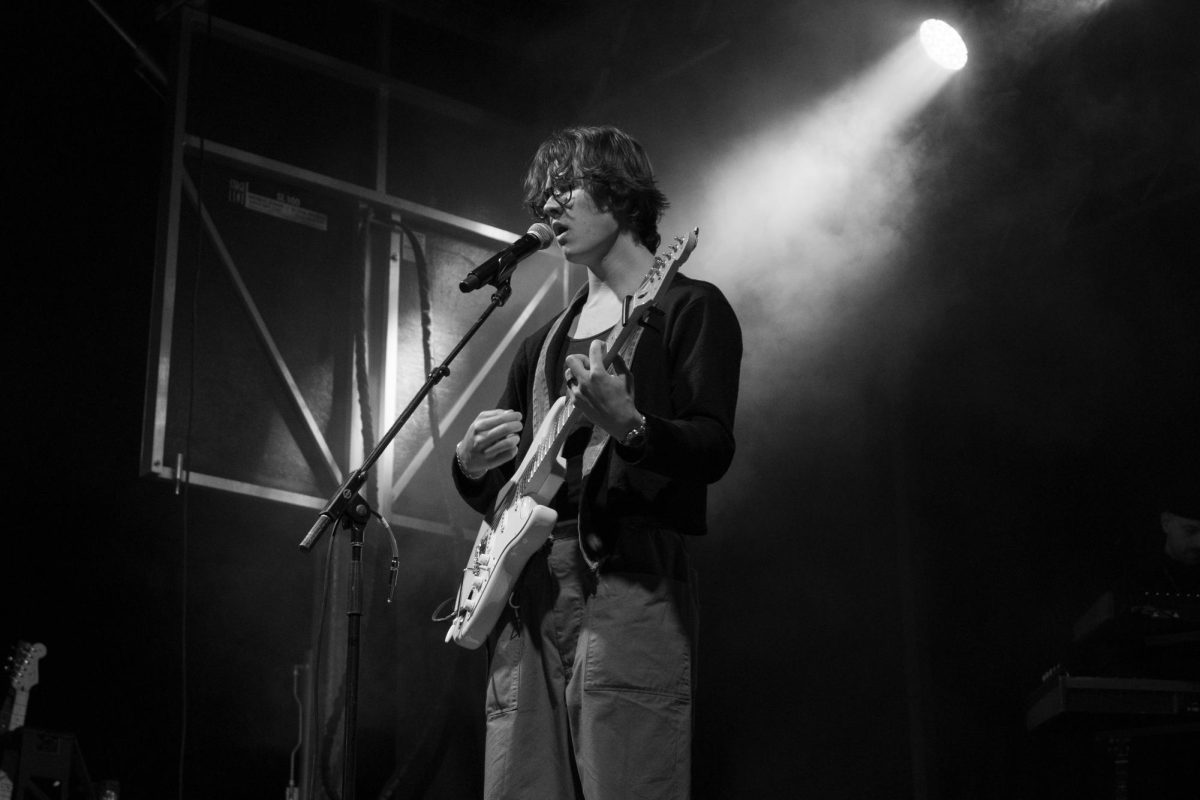

U researchers are working to develop a less-complex six-legged robot using the same idea of a robot that can walk and roll if necessary.

“For a hybrid robot, there’s a lot of design into getting it to do both,” said Marshall Floyd, a doctoral student in mechanical engineering who is involved in the research. “You use a lot less energy to roll, and this could be used to get into tighter spaces.”

Floyd uses a plug-in outlet and three motors to power the robot. By pushing a few buttons on a computer, Floyd can make the robot roll around and stretch out its parts to climb or walk using magnetic legs.

But the robot has some technical problems right now. To walk well, the robot needs a magnetic floor to latch onto and stay upright.

Floyd said he and another mechanical engineering graduate student, Brittany Baker, have been teaching the robot to walk in a coordinated fashion.

Mechanical engineering professor Mark Minor, who advises the project, said the department bought sensing devices to help track the movements of the robot. They also have sensors attached to the robot’s legs to make sure parts of the body don’t collide.

Minor said if the sensors were disabled, the robot wouldn’t function properly. Even if one wire were disconnected, the robot would be impaired.

“The same thing happened with the airplane that exploded over New York four or five years ago,” Minor said. “It crashed over the ocean when a wire failed and it sparked fuel in the fuel tanks.”

The robot began as a former graduate student’s thesis work, and Floyd is working on making it move on its own better by attaching a micro-controlling chip instead of wires.

Right now, the robot can only roll around once without getting caught on the wires attaching it to the wall.

“Our next step is to go to the National Science Foundation and ask for money to explore the simultaneous process of locomotion and teach the robot to walk,” Minor said.

The robot designs are continually hindered by funding, Minor said. They spend anywhere from $2,000 to $3,000 on wiring, materials and more to design and build one robot, he said.

About a year ago, the plastic top on another robot that a group of students built became cracked when it rolled across the floor too fast. The students used the same round, plastic piece for the top of the robot that is used around campus for outdoor light bulb cases, which cost about $50.

“When you’re working with a design team and don’t have a lot of money, you really have to cut some corners,” Minor said.

The broken robot is another project for graduate students in the

mechanical engineering department to work on in the future.

Most students interested in robot designs have been following a robotic track that allows them to major in mechanical or electrical engineering or computer science, but also take classes to learn about the mechanics of building robots.

The classes include a mechatronics class that makes students design and build their own robots during the semester.

Graduate students work on their own projects, which include evolving designs to help the robot work more on its own.

“When we’re learning to walk, we fall down and realize the steps are too high or low, but with a robot, they have no pain sensors,” Minor said. “We have to teach them to walk.”

Floyd said other professors in the department are designing robots to trot or jump.

“I’m interested in building a robot to move faster,” Floyd said.

To learn more about robot designs, visit www.mech.utah.edu/about/MEiscool.html.

Lennie Mahler

Lennie MahlerMarshall Floyd, a PhD. student studying the robotics track within the mechanical engineering department, demonstrates how a robot named the “Rolling disc biped” can curl up and roll for more energy-efficient movement.