3D printing is the process in which material is solidified under computer control. Used to create a physical object from a three-dimensional digital model, 3D printing involves the laying down of many thin layers of a material in succession. 3D printing is used in both rapid prototyping and additive manufacturing.

In the past few years, this form of technology has made numerous advancements. The printing of everyday items to the printing of food has now become common.

There are many different materials that can be used for 3D printing. These include ABS plastic, nylon, glass, materials like epoxy resins, a range of metals, wax and now, stem cells.

The University of Utah’s own biomedical engineering assistant professor Robby Bowles has recently co-authored an academic paper with former U biomedical engineering masters student, David Ede. The article, published in the “Journal of Tissue Engineering, Part C: Methods,” focuses on their new 3D printing method. This new method involves printing human cells to produce tissues such as ligaments, tendons and spinal discs.

An individual can easily damage an important ligament, tendon or rupture a disc. This new method of printing allows the replacement tissues to be printed and implanted into the damaged areas. In the official press release from UNews, Bowles states that this method “will allow patients to receive replacement tissues without additional surgeries and without having to harvest tissue from other sites, which has its own source of problems.”

Currently, harvesting tissue from other sites produces tissues of poor quality. These are either harvested from another part of the patient’s body or from donated cadavers.

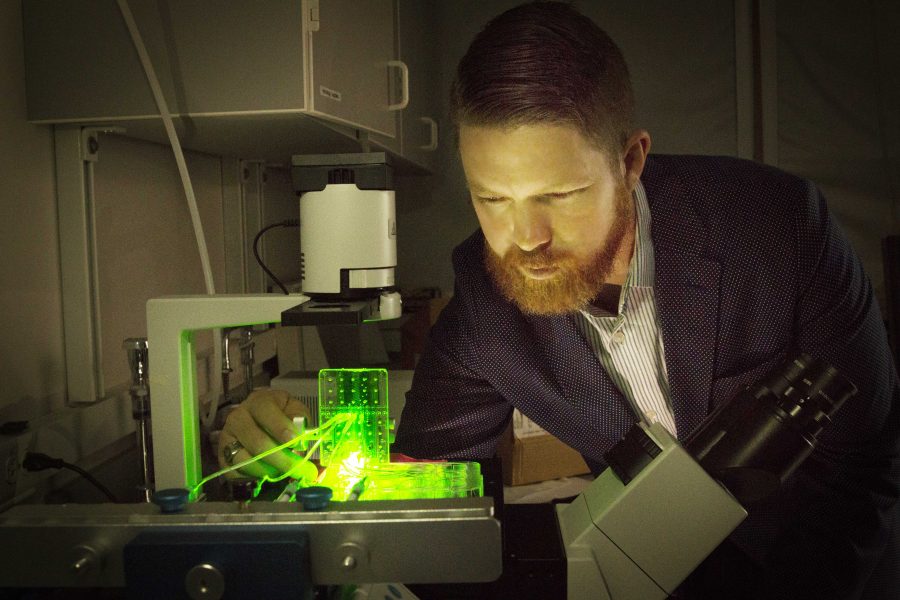

Bowles, who specializes in musculoskeletal research, has taken two years to research the 3D printing method with his team. Working with the Salt Lake-based company Carterra, they have developed ways to grow stem cells taken from the patient’s own body fat and print them onto a layer of hydrogel. These printed stem cells then grow in vitro before being implanted into the patient. The team used a printer from Carterra that is typically used to print antibodies for cancer screening applications, according to UNews. Using a specialized printhead, the team has extreme control and can arrange the cells in complex patterns. The printhead allows the researchers to place cells exactly where they want them to go.

For those that are unfamiliar with 3D printing, the printhead is a component in a printer that assembles the information. It translates it into the printing medium.

To prove their control over the printing process, the team genetically altered a set of cells to glow a fluorescent color in efforts to visualize their final product.

Currently, the design is only for the creation of tendons, ligaments and spinal discs. However, Bowles states that this method “could be used for any type of tissue engineering application.”

The future of biomedical research is promising. The printhead that the research team has developed could be used in the future to possibly print an operational human organ. The impact this development could have on the medical community would be profound.